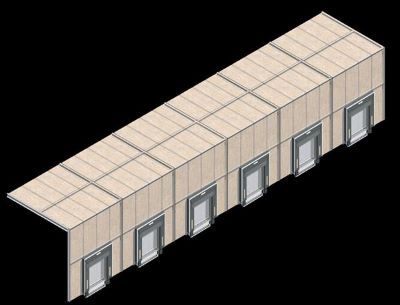

Sterling Structural, a leading manufacturer of cost-effective, prefabricated mass timber and hybrid structural systems in North America, today announced the launch of its CLTimber Bay System, a comprehensive building solution specifically designed for industrial and commercial projects including warehouses, data centers, and large-scale retail facilities.

The CLTimber Bay System combines the environmental benefits of mass timber with the speed and efficiency of a pre-engineered solution. Building on Sterling’s expertise in delivering large-scale industrial projects, the system addresses the growing demand for sustainable industrial and commercial buildings as corporate real estate priorities shift toward smarter building systems that support both people and the planet.

“As the industrial and commercial sectors evolve, developers are prioritizing building systems that deliver both environmental performance and construction efficiency,” said Michaela Harms, Vice President of Mass Timber at Sterling Structural. “Our CLTimber Bay System responds to this shift by providing a sustainable and turnkey mass timber solution that’s optimized for performance, flexibility, and constructability—delivering on site, on time, and on budget.”

Unlike traditional mass timber suppliers, Sterling Structural provides a complete, fully engineered building solution that includes structural design, CLT supply, structural steel, connection hardware, and installation through its trusted network of partners. This integrated approach streamlines procurement, reduces job site coordination, and keeps projects on track with domestically sourced and manufactured materials that are reliably delivered to the project site.

Key features of the CLTimber Bay System include:

- Accelerated Construction: Prefabricated panels can be installed with factory-applied Weather Resistant Barrier (WRB) to fast-track envelope completion.

- Simplified Installation: CLT provides a continuous structural surface, making attachment of racking, mechanical systems, or tenant improvements straightforward without additional blocking or costly field coordination.

- Flexible Design: Optimized grids support future adaptability for evolving industrial and commercial needs.

- Environmental Performance: Dramatically reduced embodied carbon compared to traditional tilt-wall construction using 100% domestically grown, regenerative timber.

Sterling Structural and its complementary product, engineering and installation partners provide comprehensive environmental product data, material weight analyses, logistics benefits, and schedule advantages over traditional tilt-wall construction. The system supports developers seeking U.S.-based supply and measurable sustainability outcomes while maintaining construction efficiency and cost-effectiveness.

Sterling’s TerraLam® structural product line provides a competitively priced, mass timber panel that is designed for seamless integration into wall, floor, and roof applications. Sterling Structural serves as a one-stop shop for mass timber or a hybrid structural shell. Its panels are certified to the PRG 320 performance standard by the International Code Council and have an Environmental Product Declaration (EPD) third-party verified by EPD Hub.

About Sterling Structural

Sterling Structural is a division within Sterling Solutions, America’s leading manufacturer of sustainably-sourced, domestically-produced, high-quality and cost-effective Cross Laminated Timber (CLT) mats, panels and systems. Our TerraLam® structural product line provides a competitively priced, mass timber panel that is designed for seamless integration into wall, floor, and roof applications. Sterling Structural serves as a one-stop shop for mass timber or a hybrid structural shell. Our panels are certified to the PRG 320 performance standard by the International Code Council and have an Environmental Product Declaration (EPD) third-party verified by EPD Hub. Sterling has manufacturing facilities in Phoenix, Ill., and Lufkin, Tex., with an annual production capacity of 700,000 cubic meters. More information is available at www.sterlingstructural.com.

Feature Image Courtesy of: Sterling Structural