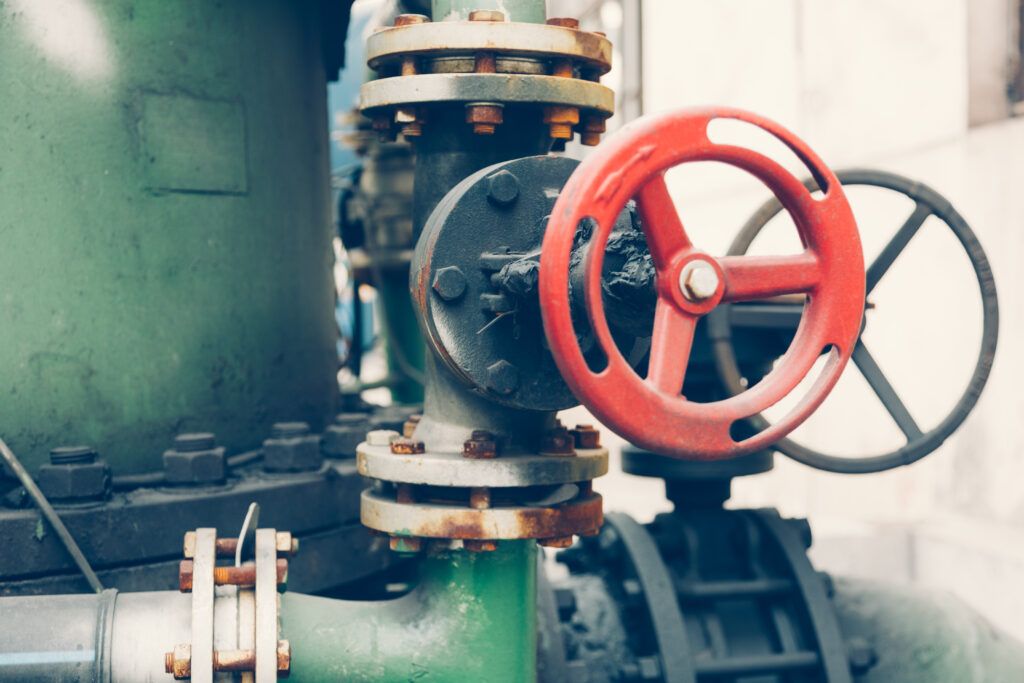

Pressure relief valves (PRVs) are crucial components in many industrial systems, designed to protect equipment and personnel from the dangers of overpressure. In Australia, adherence to stringent regulations and standards is essential for ensuring that each pressure relief valve operates safely and effectively. This blog explores the key Australian regulations and standards governing pressure relief valves, their impact on safety, and how compliance ensures optimal performance.

Understanding Pressure Relief Valve Regulations in Australia

Pressure relief valve regulations are a set of standards and guidelines established to ensure that PRVs perform reliably and safely under high-pressure conditions. These regulations cover various aspects of valve design, installation, testing, and maintenance to prevent accidents and equipment failures.

Purpose of Regulations:

- Safety: Protects against overpressure scenarios that could lead to explosions or equipment damage.

- Performance: Ensures valves operate within specified pressure ranges and function correctly.

- Consistency: Provides uniformity across industries and applications, ensuring reliability.

Key Australian Regulations and Standards

AS 1271: Pressure Relief Devices

One of the primary standards for pressure relief valves in Australia is the AS 1271 standard, which is part of the broader suite of Australian standards for pressure equipment.

- AS 1271: This standard specifies requirements for pressure relief devices, including design, installation, and testing. It ensures that valves meet safety and performance criteria suitable for Australian conditions.

AS/NZS 60079: Electrical Equipment for Explosive Atmospheres

For pressure relief valves used in explosive atmospheres, compliance with AS/NZS 60079 is crucial.

- AS/NZS 60079: This standard outlines requirements for electrical equipment used in hazardous areas, including those that may be subject to overpressure conditions. It covers aspects such as safety, testing, and installation to ensure equipment performs safely in explosive environments.

Australian Dangerous Goods (ADG) Code

The Australian Dangerous Goods Code provides guidelines for handling and storage of dangerous goods, which often involves pressure relief systems.

- ADG Code: While not exclusively for pressure relief valves, this code includes provisions related to the management of pressure and safety measures for dangerous goods, influencing the requirements for pressure relief systems used in these contexts.

Impact of Regulations on Safety and Performance

Adhering to pressure relief valve regulations is crucial for maintaining safe operation in industrial systems. Regulations help prevent overpressure situations that could lead to catastrophic failures or hazards.

- Pressure Relief Accuracy: Regulations ensure that valves are accurately calibrated to release pressure at the correct set points, preventing accidental explosions or equipment damage.

- Reliability: Regular testing and maintenance requirements help ensure that valves function reliably when needed, reducing the risk of system failures.

Maintaining Performance

Regulatory standards also help maintain the performance of pressure relief valves, ensuring they operate efficiently and effectively.

- Consistency: By following standardized guidelines, manufacturers produce valves with consistent quality, ensuring they meet performance expectations.

- Testing Procedures: Regulations specify rigorous testing procedures to validate valve performance under various conditions, ensuring they function correctly in real-world applications.

Compliance and Certification

To ensure compliance with Australian pressure relief valve regulations, organizations should follow these steps:

- Select Certified Products: Choose valves that are certified to meet Australian standards such as AS 1271. Certification indicates that the valve has been tested and meets the required standards.

- Regular Inspections and Testing: Conduct regular inspections and testing to ensure valves continue to meet safety and performance requirements. Follow guidelines for periodic maintenance and calibration.

- Documentation: Maintain thorough documentation of valve specifications, testing results, and maintenance records to demonstrate compliance with regulatory standards.

Certification Bodies in Australia

Several organizations provide certification and verification services for pressure relief valves:

- Standards Australia: The primary body responsible for developing and maintaining Australian standards, including those for pressure relief devices.

- Australian Certification Authorities: Organizations such as SAI Global and TÜV Rheinland provide certification services based on Australian standards.

Challenges and Considerations

While regulations are essential for safety, they can be complex and vary by region and industry. Organizations must navigate these complexities to ensure compliance.

- Regional Variations: Different states and industries in Australia may have varying standards and regulations. It’s crucial to understand and adhere to the specific requirements applicable to your region and sector.

- Keeping Up-to-Date: Standards and regulations can change over time. Stay informed about updates and revisions to ensure ongoing compliance.

Balancing Cost and Compliance

While meeting regulatory requirements is essential, it’s also important to balance cost considerations.

- Initial Costs: Certified valves and compliance procedures may involve higher upfront costs. However, these costs are often outweighed by the benefits of enhanced safety and performance.

- Long-Term Savings: Properly functioning valves and adherence to regulations can prevent costly accidents, equipment failures, and downtime, resulting in long-term savings.

Examples of Australian Industry Applications

Mining and Resources

In Australia’s mining and resources sector, pressure relief valves play a critical role in managing the high-pressure systems used in extraction and processing.

- Regulatory Compliance: Mining operations must adhere to strict Australian standards to ensure safe and reliable pressure management.

Oil and Gas

The oil and gas industry uses pressure relief valves in various applications, including drilling and refining.

- Safety Standards: Compliance with Australian standards such as AS 1271 is essential for managing the pressures associated with these processes.

Water and Wastewater Management

Pressure relief valves are used in water treatment and wastewater management systems to ensure safe operation under varying pressures.

- Environmental Compliance: Ensuring valves meet Australian standards helps manage pressure and maintain environmental protection.

Final Thoughts

Pressure relief valve regulations and standards in Australia are vital for ensuring the safety, performance, and reliability of industrial systems. By adhering to these regulations, organizations can protect their equipment, personnel, and the environment from the risks associated with overpressure. Understanding and implementing the relevant standards, conducting regular maintenance, and selecting certified products are key steps in achieving compliance and maintaining optimal valve performance. As regulations evolve, staying informed and proactive will help ensure continued safety and efficiency in your systems.

The 2024 virtual Men’s Round Table will be held Q4, 2024, date TBD.

The 2024 virtual Men’s Round Table will be held Q4, 2024, date TBD.