Urbahn Architects and contractor Zafra Minhas Construction (ZFM) have completed flood mitigation and storm resiliency upgrade at the IND B and D Lines subway station at 155th Street and Frederick Douglass Boulevard in Upper Manhattan for MTA Construction & Development (MTA C&D).

In the aftermath of Superstorm Sandy, the MTA Capital Plan included this station as one of a group of seven stations and one fan plant throughout the New York City subway system that required mitigation measures to prepare for future superstorms to prevent the loss of life, reduce operational disruption, and minimize repair costs. Ultimately, this $32 million federally funded project addressed flood mitigation and resiliency for a range of stations, tunnel portals, fan plants and other critical assets necessary for continuing operations of the MTA.

In addition to the 155th Street Station, the locations included: the Houston Street station (Manhattan), 103rd Street station (Manhattan), 110th Street station (Manhattan), 138th Street Station-Grand Concourse (the Bronx), Roosevelt Island Station (part of the Borough of Manhattan), and 21st Street Station and fan plant (Queens). Urbahn was the project architect and ZFM the general contractor for all seven sites.

Local conditions determined the specific scope of work at each station. The 155th Street station is located a mere 300 feet from the Harlem River, in an area that was completely flooded during Sandy and is vulnerable to storm surge events. Water intrusion during past weather events has left this station temporarily inoperable, which necessitated upgrades. This project included hardening the perimeter around the entry stairs with an innovative resilient railing and flood stop log system to prevent future water infiltration into the station, as well as the provision of watertight doors in lower-level utility rooms.

According to Natale Barranco, AIA, LEED AP, Urbahn Architect’s Principal-in-Charge, “This $1.8 million project was particularly challenging as the station has only one point of access that had to remain fully operational during construction. Urbahn worked closely with MTA C&D and with the contractor, Zafra Minhas Construction, to ensure that the work was adequately phased and remained on schedule.”

“The 155th Street Subway Station flood mitigation upgrade was one of a series of natural disaster mitigation construction projects Zafra Minhas has successfully completed for the New York City Transit Authority and the MTA since 2016. Totaling $72 million in construction value, these projects have strengthened the resilience of New York City’s public transportation infrastructure and called for installation of innovative flood protection systems such as Pressray stackable flood logs, ILC Dover Flex-Gate movable flood barriers, and FloodBreak MCDs,” said ZFM President and CEO Gilles F. Kacha.

ARUP served as project manager and provided structural and MEP engineering services. The contract manager was URS/AECOM. In addition to Barranco, Urbahn’s team included Ranabir Sengupta, AIA, Design Principal; Nandini Sengupta, LEED AP, Project Manager; and Jonathan Ruiz, Associate – Designer. ZFM’s Project Manager was Ennis Ozgul.

Design Elements

The entrance to the 155th Street underground station is a sole quadruple-wide staircase leading down from the street level to a full-length mezzanine that spans the platform and tracks below it. The staircase opening on the street level is 28-feet-6-inches wide by 21-feet long on the sides. A traditional K-railing, the open cast iron fencing that is used throughout the NYC transit system, originally surrounded the entrance on three sides. Neither the fencing nor the open stair offered any protection against flood waters. Due to its location adjacent to the Harlem River, the neighborhood is within a FEMA flood zone, and has a 100-year flood level of five feet above grade.

“In order to prevent flood waters from cascading into the subway entrance, Urbahn designed a retention wall system that is capable of withstanding the static and impact loads of up to 65-inches of water,” said Nandini Sengupta. The design had inherent challenges. First, the walls needed to be more than five feet high to retain the potential storm surge, but could not be opaque due to safety concerns that required the maintenance of sight lines from the street level into the entry stair. Second, the entrance side of the stair was too wide, at more than 28 feet, to accommodate a permanent hinged or sliding flood gate. “The design team researched and identified materials and systems that would meet the design goals and developed two integrated design solutions to address the challenge of protecting the unusually wide stair entrance from storm water. The selected solutions included a stackable log system,” continued Nandini Sengupta.

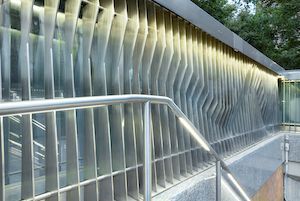

A high strength structural glass flood wall, anchored to the original concrete coping that surrounds the sides and rear perimeter of the entry, was engineered to replace the K-rail and its concrete curb. Arup performed an extensive inspection, including exploratory probes, and determined that the coping substructure was in good condition and would support the new components. Steel tube posts, 4” x 12”, spaced 4 feet on center, were anchored into the existing concrete coping and a new concrete curb was poured to encase the lower 14 inches of the posts. The walls were then encased on both sides with 9/16” tempered laminated glass, with a SentryGlas 0.060” Trosifol interlayer to create a 12” thick partition. The glass was manufactured by Guardian Glass, fabricated and tempered by Eastern Glass Resources of Harrison NJ, and installed by Mid-State Construction Corporation of North Arlington, NJ. A stainless-steel plate, sloped to prevent debris from accumulating, caps the top of the wall, and structural silicone seals all joints to provide a watertight assembly. The walls terminate at two six-foot-six-inch-high pillars located on each side of the top stair landing. Both the posts and the new concrete curb are faced with white and gray ‘Silver Cloud‘ marbleized granite that was fabricated and installed by Miller Druck Specialty Contracting of NYC.

“To prevent damage or vandalism of the glass panels, Urbahn designed a stainless-steel rib veneer, anchored to the concrete base and to the rail top cap, that is easily detachable to allow for the maintenance of the glass panels,” explains Ranabir Sengupta. The ribs, also fabricated and installed by Mid-State, consist of a series of custom vertical ¼-inch polished steel plate fins, spaced at 4 inches, that are contoured to visually create a series of sinuous curves that are reminiscent of the headwaters that they are designed to contain. The new wall design creates a virtually clear glass barrier with direct line of sight from within the staircase and mimics the open feeling of the original K-railing.

“To address water resiliency across the stair entry platform, Urbahn designed a removable flood wall using stackable stop logs model FL-HD from Pressray of Wassaic, NY to span the entire 28-foot width of the stair landing,” explained Urbahn Associate – Designer, Jonathan Ruiz. As the maximum log length is typically 8 feet 6 inches, four separate sections of log wall were required to close the gap. The logs are a six-foot high series of interlocking aluminum channels with integral compression gaskets that are supported by brackets on three intermediate movable pier supports and permanent stainless steel extrusions mounted on the granite pillars at the sides of the stair landing.

According to ZFM’s Project Manager Ennis Ozgul, “The stackable logs assembly was pressure tested during construction to confirm that it will be able to resist water infiltration from a potential five-foot storm surge. The pier supports and the horizontal logs are stored in a newly constructed mezzanine level storage area when not in use and will be deployed by a station attendant once local authorities announce a projected surge event.”

The renovation included additional upgrades and new design elements. The three existing handrails that divide the stair into four aisles, as well as the wall-mounted railings on each side of the stair, were replaced with new schedule 40 stainless steel pipe rails by Wagner Collaborative Metal Works of Milwaukee, WI. Linear LED Lumenlinear Asymmetric light strips, manufactured by Wagner Architectural Systems, have been mounted under the handrails, as well as below the edge of the stainless-steel flood wall cap, to provide enhanced pedestrian safety. A cast iron light pole with the MTA’s current standard white and green globe, manufactured by JC MacElroy of Piscataway, NJ, replaced the previous fixture. The original stair treads and risers were in good condition and were cleaned. A metal sign marking the B and D train line station in MTA standard font is mounted on the rear flood wall and was custom sized to match the scale of the six-foot-high fencing.

The project also included the replacement of four single doors and one double door at the mezzanine Electrical Distribution Room and other communications and utility rooms with new watertight flood protection doors by Pressray. This work will secure essential communications and electrical equipment in the event of future water infiltration.

Construction Challenges

The stair is the only entrance to the 155th Street station and had to remain accessible to pedestrians throughout construction. “ZFM relied on their extensive MTA project experience to design and implement a detailed Maintenance and Protection of Traffic (MPT) plan to ensure that pedestrians could safely use the stairs while work progressed,” said Ozgul.

As a starting point, ZFM constructed eight-foot-high barriers around the sides and rear of the stair opening to enclose the grade level work area surrounding the railing. Protecting the stair side of the railing was more challenging. Since the stair has four lanes separated by handrails, ZFM used this division to create protection zones in a phased approach. First, a three-foot-deep work platform was constructed over the portion of the two center aisles closest to the rear wall to enable workers to access the center rear railing section while still permitting pedestrian access to all four stair lanes. In the second phase, initially the left and then the right aisles were restricted to pedestrians as work in each of those sections was performed. Finally, the center two aisles were restricted as the final segments of the project were completed.

Construction, which was performed over an eight-month period, took place after the start of the COVID epidemic. ZFM stringently followed relevant New York City and State COVID protocols to ensure worker and pedestrian safety. Work was performed at night when pedestrian traffic was at a minimum to reduce impact on subway riders.

Urbahn Architects

Urbahn Architects is a full-service planning and design firm based in New York City. Since its founding in 1945, Urbahn has designed projects for organizations and institutions that operate in the transportation, residential, healthcare, education, justice, science, hospitality, multi-family residential, and infrastructure sectors. The firm served as the architect for some of the nation’s most iconic structures, including the Vehicle Assembly Building and Launch Control at Kennedy Space Center in Cape Canaveral, FL, and the Fermi National Accelerator Lab in Batavia, IL.

Urbahn’s annual domestic and international project workload exceeds $500 million in construction value. ENR New York magazine recently recognized Urbahn as the 2019 Design Firm of the Year. Building Design & Construction ranks Urbahn as the 102nd largest architectural firm in the U.S. Four principals lead the firm: Donald E. Henry, Jr., AIA, LEED AP; Natale V. Barranco, AIA, LEED AP; Rafael Stein, AIA; and Ranabir Sengupta, AIA, LEED AP.

The firm’s transportation project portfolio includes the New York City Transit subway station flood mitigation resiliency program; renovations of multiple MTA subway stations in New York City; numerous projects for the Long Island Rail Road and New Jersey Transit; Newark City Subway Improvements in Newark, NJ; and rehabilitation of six train stations on the IRT White Plains Road line in the Bronx, NY.

Urbahn’s other recent commercial, institutional, and public work includes the $70 million Tides North multi-family residential development in Arverne, NY; New York City Hall Mayoral Offices and Emergency Situation Center and Public Health Lab Redevelopment Master Plans in New York, NY; Centro Medico Correccional in Bayamon, PR; the Jersey City Municipal Services Complex in Jersey City, NJ; the SUNY New Paltz Engineering Innovation Hub in New Paltz, NY; the Lehman College School of Nursing in the Bronx, NY; the Usha Martin University Master Plan in Ranchi, India; Columbia University’s Baker Field Facilities Master Plan in New York, NY; the P.S. 253Q Elementary School in Queens, NY; and the P.S. 144Q addition in Forest Hills, NY.

Zafra Minhas Construction

Three general contractors, Zafer Construction, FRAMACO International, and Minhas Construction founded Zafra Minhas Construction LLC (ZFM) in 2016 to pursue construction projects in the MTA’s Superstorm Sandy mitigation capital program.

With over 60 years of combined experience in construction, ZFM brings a wealth of resources to its projects, including a seasoned management team and an extensive portfolio of successfully completed projects. FRAMACO and Zafer have completed infrastructure and construction projects for various U.S. government agencies that exceed $2 billion in construction value. Minhas has a solid past performance completion history with the MTA, with expertise in a broad range of masonry services.

Since its inception, ZFM has completed two contracts with the New York City Transit-MTA, valued at $72 million. Both contracts called for furnishing and installing flood protection systems at various NYCT facilities.