Automated Testing Solutions, Inc. (ATS) is an American business success story. Located in Circle Pines, a suburb of the Twin Cities in Minnesota, ATS was founded in 2002 by Mike and Jane Wakumoto after Mike’s mechanical engineering position in a testing lab was eliminated.

Entrepreneurs at heart and with an opportunity to begin something new, Mike and Jane immediately began designing and manufacturing window and door testing equipment in their garage — and in a pole barn volunteered by Mike’s in-laws, Harold and Dona, owners of a hobby farm in central Iowa. “Without faith in God, family support and living in this land of opportunity, ATS would have never succeeded, let alone even started,” says Mike.

Two decades later, ATS has a thriving customer base throughout the United States and Canada and is a leader in the window and door test equipment industry. Their proprietary test equipment is used to simulate weather events and to determine product reliability and compliance with regional, national and international codes.

ATS products range from portable test equipment used to determine air and water leakage to large scale laboratory equipment simulating storm debris under very high wind pressures that occur in severe weather events such as tornados and hurricanes.

The Situation and Opportunity

According to the National Oceanic and Atmospheric Administration, “The U.S. has sustained 348 weather and climate disasters since 1980 where overall damages and costs per event reached or exceeded $1 billion (including CPI adjustment to 2023). The total cost of these 348 events exceeds $2.510 trillion.”

Since windows and doors are especially susceptible to damage during storms with high winds and rain, it is imperative that manufacturers, builders, landlords, installers — and even legal teams — have a way to test windows, doors and installations.

In-House Design and Manufacturing Testing

Before selling to the general public, manufacturers must test their window and door designs — whether in the laboratory at the design phase or at the end of the production line during quality checks — to ensure compliance with the industry standards of ASTM International, American Architectural Manufacturers Association (AAMA), Window & Door Manufacturers Association (WDMA) and CSA Group.

Installation Testing

Properly installed windows and doors can help builders and landlords prevent water from penetrating their buildings, avoiding costly mold and rot repairs. Yet the perfect install is impossible to detect with the naked eye.

Litigation Case Testing

In multimillion-dollar homes, disputes can often arise over costly water damage. Legal teams investigate to determine whether the fault lies with the window and door designer/manufacturer or the installer.

The Solution

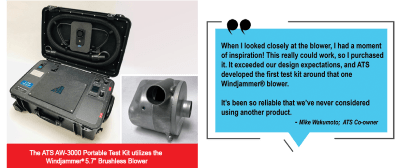

With these three testing applications in mind, the ATS team recognized the need for a cost effective automated portable air leakage and water infiltration test kit. After years of development, ATS recently released its eighth generation AW-3000.

This portable test kit performs automated air infiltration/exfiltration and water penetration testing to ensure that:

• Newly designed and manufactured windows and doors meet the current industry standards.

• Window and door installations are sound, preventing costly repairs for builders and landlords.

• Litigation cases are disputed fairly based on accurate and repeatable data.

As the ATS team was developing the first-generation test kit, engineers knew they needed a strong and reliable air vacuum and pressure source. Unsure about which direction the test kit would take, Wakumoto stumbled upon a Windjammer® 5.7″ brushless blower by Bison at a surplus store.

“When I looked closely at the blower, I had a moment of inspiration! This really could work, so I purchased it. It exceeded our design expectations, and ATS developed the first test kit around that one Windjammer blower. It’s been so reliable that we’ve never considered using another product,” said Wakumoto.

Windjammer 5.7″ Customization, Product Durability and Reliability Provide Competitive Advantage

Windjammer 5.7″ Customization

Wind can push air and water through window and door seals. Therefore, when testing windows and doors, it is essential for the equipment to simulate wind by creating a constant, steady pressure behind the surfaces under test. The Windjammer 5.7″ blower produces this differential pressure for the AW-3000.

It is critical for the AW-3000 to precisely control the pressure generated from the Windjammer blower. Adding a PID control circuit to the AW-3000 should have enabled test technicians to have the level of control over the blower speeds and pressure they desired.

However, one challenge was that the original off-the-shelf blower purchased by ATS had software with closed-loop speed. This functionality is standard for Windjammer 5.7″ because the markets that the blower is normally sold into do not have the need for as sophisticated a control as ATS. As a result, the AW-3000 and blower controller competed for control of the speed of the blower. Therefore, the AW-3000 could not produce steady pressure generation.

Bison application engineers and ATS engineers worked together to modify the control scheme in the blower to be open-loop, allowing the ATS controller to have sole control of the blower speeds within the blower’s operational limits. The system could now produce stable pressures for testing.

The second challenge was that the Windjammer blower kicked on at a higher RPM than the application required, applying too much immediate pressure to the test specimens. Bison engineers throttled down the blower’s starting speed and minimum control voltage setting to meet the ATS RPM specifications. This simple change has made the AW-3000 the ideal kit for testing both operable and fixed windows with varying tolerance tightness levels.

“Customizing the Windjammer 5.7″ blower to solve our two main issues enabled the AW-3000 test kit to provide constant, steady pressure for the most accurate results in the industry and has empowered our customers to test a greater variety of windows and doors with varying sealing tolerance levels. The blower’s customized functionality gives ATS quite a competitive advantage,” said Wakumoto.

Windjammer 5.7″ Durability and Reliability

In addition to customizing the blower to his requirements, Wakumoto appreciates the durability and reliability of the Bison product. He estimates that he now has more than 200 Windjammer blowers in use in the field and laboratory and recalls only one issue which was quickly resolved.

“Our test kits are in many conditions, some extreme. They are thrown into the back of pickup trucks, checked as luggage at airports, jolted downstairs or slugged through construction sites where there is dirt, dust, rain, and more,” Wakumoto said. “And the AW-3000, which integrates the Windjammer 5.7” brushless blower, continues to be extremely reliable,” added Wakumoto.

He also values how quiet and compact the blower is while delivering significant power and flow for its size.

What’s Next?

As ATS continues to expand and increase its customer base, its reputation and success have not gone unnoticed by the international market. The company has received inquiries from countries in Asia, Europe and South America, demonstrating the growing demand for their product and expertise. With its track record of providing innovative testing solutions for the window and door industries, ATS is well-positioned to expand its expertise and knowledge to businesses around the world.

Results

The benefits of using the AW-3000 test kit are numerable:

ATS Customers Save Time, Money and Manpower

Traditionally, setting up the test then reading and documenting the data required at least two skilled technicians. Automating window and door testing is a game-changer for ATS customers who can now conduct tests single-handedly, without the need for an extra person.

The AW-3000 saves ATS customers hundreds of hours and thousands of dollars — and importantly, the hassle of finding and employing more skilled labor per test!

The Industry’s Most Accurate Data

Before the introduction of the AW-3000, data was collected manually, often handwritten by a team of technicians or employees. This process captured illegible information that required reviewing and editing. Without doubt, human error compromised the accuracy of the results.

With the AW-3000, data is automated and collected by computer, providing the most precise information that can be easily read and quickly analyzed to guide appropriate actions.

AW-3000 is Becoming the Industry Standard

With its reputation for reliability and durability, the AW-3000 is quickly becoming the industry standard, as evidenced by this quote from an ATS customer.

“After almost a year of usage, the AW-3000 has exceeded my expectations. As a FAPC-certified professional, I strongly believe that this equipment should be the industry standard for testing. It is highly reliable and eliminates any potential human errors associated with monitoring the test pressure. This equipment has elevated the formality of all reports and taken my work to the next level. Thank you for producing such a remarkable product.” — One of many satisfied ATS customers

Feature Image Courtesy of: ATS