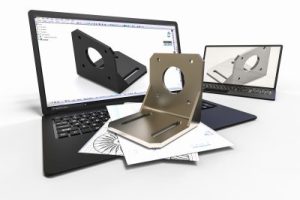

Computer-Aided Design (CAD) is a software tool that has brought many changes in the manufacturing industry. This technology creates elaborate two- or three-dimensional (2D and 3D) models of real-world objects.

CAD software has made optimizing designs before manufacturing easier for designers and engineers. This has increased efficiency and productivity, not to mention cost savings in manufacturing.

This article will explore five applications of CAD in manufacturing, ranging from prototyping and simulation to quality control and documentation.

- Greater Collaboration

CAD technology has enhanced collaborations between different teams and departments during manufacturing. Using CAD, team members can coordinate their efforts, share information, and provide real-time feedback on product designs simultaneously. That said, there’s no need for lengthy email chains, and time-consuming meetings are significantly reduced.

As such, manufacturers can create 3D models for their customers using CAD software technology. This allows them to simulate how products perform in the real world. It lets the customers better understand the product’s design and give feedback before manufacturing.

While at it, the design team can analyze design elements within a shorter time frame. In so doing, manufacturers can speed up the product development cycles and launch them faster. Using CAD technology, teams can work more efficiently, reduce errors, and improve communication throughout product design and development.

- Product Documentation

Manufacturing teams can create detailed and accurate 2D and 3D models of products, along with all their components and assemblies, using CAD software. This has made the product development process faster and more efficient, mainly because changes and modifications can be made immediately and accurately.

Furthermore, CAD software has enabled manufacturing teams to produce high-quality product documentation. This includes technical drawings, bills of materials, and assembly instructions, which can be shared and communicated more effectively with stakeholders.

The CAD file format is handy as it allows easy data exchange between computer systems and software applications. As a result, manufacturers can easily create detailed product documentation essential for efficient production processes.

- Advanced Prototyping

When manufacturing, a product can only be seen as complete after a series of prototypes and tests. A prototype is a physical model created to test a product’s functionality before manufacturing. This process allows manufacturers to find flaws and address them.

Manufacturers can produce comprehensive 3D models using CAD. It has enabled advanced prototyping, significantly lowering the time and expense associated with conventional prototype techniques. As a result, engineers can create, test, and improve their prototypes quickly and efficiently utilizing CAD software. This also enables them to test and improve product concepts before moving forward with mass manufacturing.

Companies have been able to release new goods more quickly and affordably because of CAD. They produce more accurate, robust, and valuable prototypes without relying on expensive machinery or specialist skills. With this technology, manufacturers can identify and fix design issues early in the process, significantly improving the overall product quality.

- 3D Modeling

3D modeling is a three-dimensional representation of an object using specialized software. It’s virtual models of products in the manufacturing process. And these 3D models can be viewed from any angle and manipulated in real-time.

As a result, 3D modeling allows engineers and designers to produce exact and detailed virtual representations of objects. Using intricate shapes and geometries, CAD technology creates 3D models with all the necessary details, including material qualities, weight, and more.

A 3D model can be put to many different uses once made. It can model product behavior, make physical prototypes, and even produce production and user instructions. These models are also simple to update and modify as required. This way, quick changes and adjustments can be made to product designs.

3D models can simulate the product’s performance in different iterations. This way, other materials, and designs can be tested. The product can be optimized for performance and cost.

- Automation

CAD can help manufacturers automate their processes. It aids in developing product models, simulating production processes, and creating designs. This way, manufacturers can cut the time and expense associated with manual design and production processes using CAD.

They can make parts that are more precise and consistent than ever. Precision cuts and measurements based on virtual models have also been made possible by automation. These consequently lead to quicker manufacturing times and fewer mistakes.

Recap

Computer-aided design is a computerized technology in manufacturing with many uses. With CAD, engineers, and designers, anyone in the industry can produce complex 3D models of items. As such, CAD technology may be used for product documentation, design analysis, and prototyping. Virtual reality simulations, which can be used for product design and testing, training, and maintenance, can also use CAD technology. Furthermore, it can be designed and tested using CAD software. This can help to boost productivity and efficiency and save costs in the manufacturing sector.

Generally speaking, CAD has transformed the manufacturing industry and is essential in helping businesses design, manufacture, and maintain high-quality goods that satisfy their consumers’ expectations.